One Piece Flow Assembly Line

One piece flow to succeed the tasks need to be at uniform skill level. Due to the evolving nature of manufacturing there is increasing demand for ever smaller batch sizes and businesses need to be able to respond to this flexibly and cost-effectively.

Single Piece Flow Single Piece Flow Work Balance

With one piece flow equipment can be designed smaller and at lower cost since the need to produce huge batches of material at breakneck speed is no longer required.

One piece flow assembly line. In this video you will be able to see how a circuit board moves through Kitrons high capacity multi operational and fully automated one-piece-flow product. It should be related to the customers. If at least one task demand higher skill the worker has to be highly skilled.

The next step is to calculate takt time for. Larger assembly systems may quickly become too complex to have all on one single line. It is the fundamental element of becoming Lean.

In mass production materials move through the manufacturing process in batches which can be highly inefficient. In simple terms it means one-by-one processing of a product. Thats why its also called single piece flow and continuous flow as everything is constantly progressing and only one item is.

One Piece Flow. With Smart Factory Assembly you can easily manufacture products in fluctuating quantities and many variants. One-Piece Flow is a lean manufacturing concept that is aimed to achieve a discrete flow of work contrary to batch production approach.

This is one-piece flow manufacturing. To meet such requirements we have designed assembly and test lines for one-piece-flow manufacture with numerous product variants. This demo can be done as a production line or one-piece flow setting.

What is one piece flow. The word one does not necessarily have a literal meaning. The line which had about 10 machining centers with each experiencing typical up time.

In one-piece flow a product is completed before the next one is started typically. The intent of the line was to have one piece flow and achieve all of the touted advantages. An example would be the garment assemble process where mix and match of differently skilled take place in the batched processing system.

If you cant seem to get this issue the attention it needs implement one piece flow anyway watch the line stop make the problem visible so that you get the attention and resources needed to fix the problem. We have unreliable equipment that may break down causing downstream processes to run out of parts. When doing kaizen to design assembly lines for one-piece flow one of the first activities is measuring all of the assembly cycle times total hands-on time to build one unit and separately total automatic cycle time.

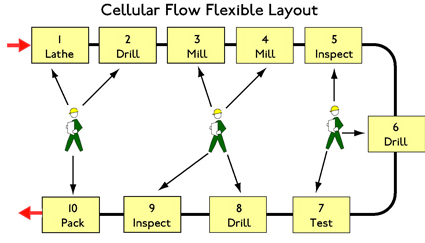

That is the right parts can be made available when they are needed in the quantity they are needed. Traditional cells with irregular material flows are replaced by U-shaped production lines within which flow is regular and paced by a cycle time and between which flow is controlled by pull signals. One key benefit of the assembly line designed according to one-piece-flow criteria lies in the fact that stocks of semi-finished products are reduced as are throughput and manufacturing times.

Fix this first. It follows the old adage -. This tutorial examines the research literature on one-piece flow.

One piece flow is all about reducing WIP to the point where everything is either waiting to be started in progress or complete. One-piece flow sometimes called continuous flow or single-piece flow is a production method used instead of traditional mass production. The idea is to punch two holes along the top margin on the card then bundle 5 cards together which must be numbered 1-5 using yarn loops.

With one piece flow work in process WIP is reduced in dramatic fashion. Sometimes referred to as single-piece flow or continuous flow one-piece flow is a key concept within the Toyota Production System. The cards need to be loosely assembled so they be flipped.

A further positive aspect of the one-piece-flow principle is that employees learn to perform all processes at the various workstations. Visualization and worker guidance can drastical. Entire assembly line benefits from lean production.

Achieving one-piece flow helps manufacturers achieve true just-in-time manufacturing. Accordingly the line was built with no storage buffers between each machining center. A single unit of product flows between different processes.

While it would be nice to have a one-piece flow between every part of the value stream it may be too much to handle in many systems. One Piece Flow manufacturing refers to the method of production that moves product along the stages of manufacturing once a single piece is complete regardless of that pieces relation to a batch or not.

Cellular Manufacturing Definition Implementation Amia Systems

![]()

Continuous Flow In The Lean Lexicon C

Cellular Manufacturing Manufacturing Cellular Change Management

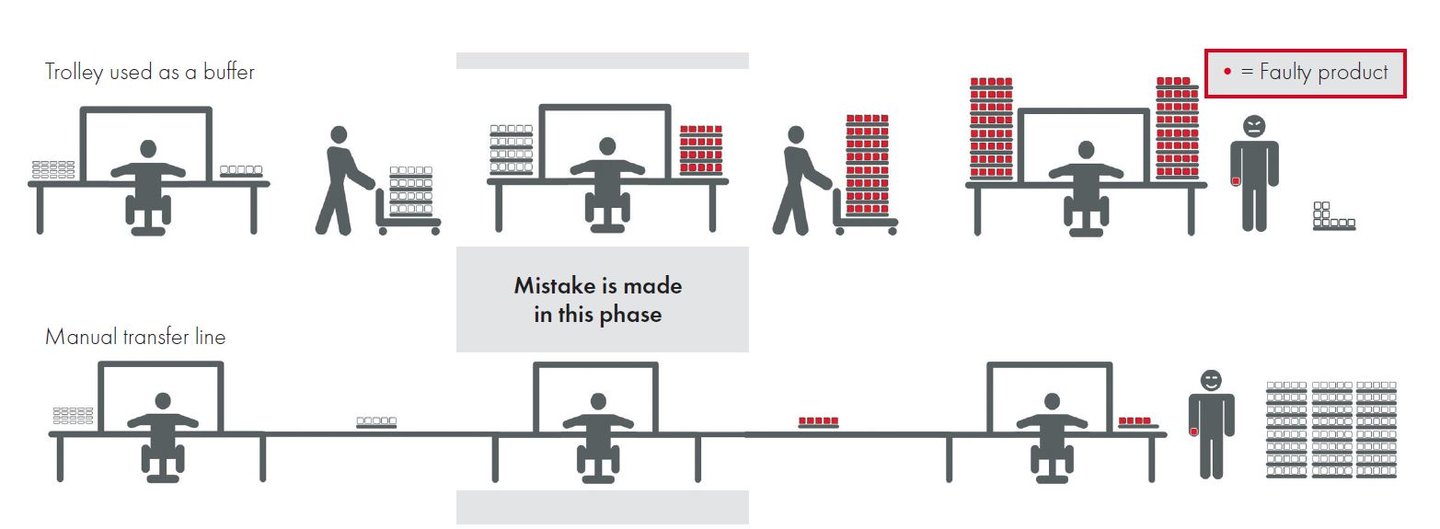

Batch Vs One Piece Flow Manufacturing Treston

Batch Vs One Piece Flow Manufacturing Treston

One Piece Flow Lean Tool Flow Single Piece Work Balance

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube

Advantages Of Cellular Manufacturing

Wire Processing Lean Manufacturing Of Cable Assemblies

Lean Six Sigma Iso Apqp Ppap Fmea 5s Kaizen 7 Qc Tools Single Piece Flow Work Balance

Batch Vs One Piece Flow Manufacturing Treston

Lean Cellular Manufacturing Processing Methods Layouts And Implementation

One Piece Flow Takt Time Kaizens Pull System Change Management Business Leadership Lean Manufacturing

Cellular Manufacturing Definition Implementation Amia Systems

Batch Vs One Piece Flow Manufacturing Treston

One Piece Flow Vs Batch One Piece Flow Vs Mass Production One Piece Flow Lean Manufacturing Youtube